Products & Services

List of products

Catalogs

Mixers

Small machines

Water treatment

Petrochemistry

Food & beverage

Medicines

Bio & regenerative medical techniques

Paints

Paper manufacturing

For experiments

Super-mix Series

Classifier

Bioreactors

Realization of Industrialization / Commercial Production / Scalability

Microbial culture

HSF ReactorAnimal cell culture

MRF ReactorAnimal cell culture

MRF-RB ReactorAnimal cell culture

VMF ReactorAnimal cell culture

VerSus ReactorRegenerative medicine

VMF-WSUB Reactor/TCSSingle-use BioReactor

iPS cell culture

HiD4×4Fittings/Options

Solutions

Development of exclusive mixers・

and impellers by purpose of useContracted numerical calculation

Evaluation of contracted cell culture

Classification performance evaluation

Environmental testing equipment

Bioreactors

HSF Reactor

MRF Reactor

MRF-RB Reactor

VMF Reactor

VerSus Reactor

VMF-WSUB

Reactor/TCSSingleUse

BioReactorHiD4x4

Fittings/Options

Fittings/Options

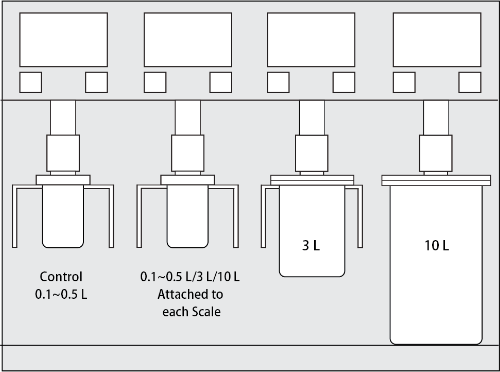

CSS II continuous culture and perfusion system connectable to Satake BioReactor

Development, Customization, and Single-use support of Exclusive Reactor in Accordance with Requirements Specifications

The feed pump automatically calculates the optimal number of revolutions from the set time, pump flow rate value (select the tube diameter) and current weight value of the electronic balance, and operation continues until the specified time. Additionally, the balance weight is monitored every 0.1 seconds during control operations, and the number of pump revolutions automatically changes. Control automatically stops once the specified time is reached. The standard included pump is generally used at medicine manufacturing sites and in culture laboratories: Watson-Marlow 120U/DV analogue control variable speed pump, and electronic balance: A&D GX3002A included as a standard.

Introducing an example system

The continuous culture and perfusion system CSS II device flow and system flow are shown in the figure. Connecting the supply and discharge pump and electronic balance as shown in the figure enables automatic culture medium replacement.

Additionally, a single CSS II can be used for culture medium replacement in two culture tanks.

■system flow

※The supply and discharge of the system flow chart can be controlled up to 2 systems.

We also provide pump systems and perfusion systems tailored to customer needs.

Please feel free to contact us regarding specialized designs for actual production, such as a single balance/pump configuration, and liquid surface control to prevent adhesion during culturing and production while conducting perfusion.

| Item | Specifications | ||||

|---|---|---|---|---|---|

| Name | Double Medium Replacement Controller | ||||

| Model | CSSⅡ | ||||

| Display range | Supply balance weight W1 | 0.01 - 3200.00 [g] *The specification can be customized in accordance with customer's requirement. |

|||

| Discharge balance weight W2 | |||||

| Supply balance weight W3 | |||||

| Discharge balance weight W4 | |||||

| Setting range | Supply pump P1 supply volume | 0.0 - 3200.00 [g] Display accuracy: ±0.5 [%] F.S. *The specification can be customized in accordance with customer's requirement. |

|||

| Discharge pump P2 discharge volume | |||||

| Supply pump P3 supply volume | |||||

| Discharge pump P4 discharge volume | |||||

| Culture medium supply / discharge time setting | 1 [minute] ~ 9999 [hours] 99 [minutes] | ||||

| Control type | Culture medium supply | Continuous culture medium supply control by weight and fluid feed pump | |||

| Culture medium discharge | |||||

| Record Data | Balance weight | W1, W2, W3, W4 | |||

| Pump discharge volume | P1, P2, P3, P4 | ||||

| MTA of outer surface | SUS304 (no paint), Indoor type, non-waterproof, non-explosion proof specification | ||||

| Installation | Tabletop | ||||

| Outer dimensions/weight | W260×D400×H225 [mm] ・Approx. 10[kg] | ||||

| Usage conditions | Temperature | 5 - 45 [℃] | Humidity | 20 - 85 [%] RH (No condensation) | |

| Electronic balance/pump | Electronic balance: A&D Company GX3002A x 2 (Option: GX-22001M) | ||||

| Pump: Watson-Marlow 120U x 2 | |||||

| Utilities | Power supply | AC100 [V], 50/60 [Hz] electrical outlet 9 gang (Main control unit, electronic balance x 4, fluid feed pump x 4) |

|||

Use with SATAKE perfusion systems

Low-temperature Incubator SLI-4090

Culture medium temperature meets temperature demands for 3 - 10℃

This incubator keeps the culture medium stable at a low temperature when used with TCS and CSSII perfusion systems.

There are two products in the lineup for use not only in labs but also in cell processing centers (CPC).

With an assumed culture medium temperature display function, this incubator enables more accurate temperature management than others.

A culture medium storage vessel equal to or smaller than the multipurpose Bag can be accommodated.

※A culture medium storage Bottle up to 2L vessel can be accommodated.

- ・Able to adjust culture medium temperature to any temperature between 3 - 10℃ ± 1.0℃ (ambient temperature 19℃)

- ・Equipped with frost removal function (once every 8 hours approx.)

- ・Equipped with automatic condensate evaporator function

- ・CPC model equipped with low pressure loss HEPA filter

- ・CPC model equipped with assumed culture medium temperature analog output function

- ・Equipped with culture medium supply tube holder

| Item | Specifications | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Name | Low-temperature Incubator | |||||||||||

| Model | SLI-4090-C | |||||||||||

| Environmental conditions | Environment temp. range | +18~22[℃] *1 | ||||||||||

| Power supply | AC100[V] 50/60[Hz] *2 | |||||||||||

| Rated current | 5[A] | |||||||||||

| Installation space | Ensure space of at least 10cm around the main unit | |||||||||||

| Temperature control | Internal temperature | Setting range | +3.0~10.0[℃] *3 | |||||||||

| Accuracy | ±2.5[℃] (at center of inside) *4 | |||||||||||

| Temperature display | Digital display (1. internal temperature display, 2.② flask interior fluid assumed temperature display) *3, 5 | |||||||||||

| Temperature correction | Single point correction | |||||||||||

| Cooling type | Refrigerator (freon gas R-134a filling volume 170 [g]) | |||||||||||

| Mixing type | Forced mixing by internal fan motor | |||||||||||

| Safety devices | Electrical leakage/overcurrent breaker, fuse, anti-icing thermostat *6 | |||||||||||

| Other functions | ・Frost removal function (forced stop of refrigerator for approx. 15 mins once every 8 hours approx.) | |||||||||||

| ・Automatic condensate evaporator function | ||||||||||||

| ・Hose holder (for O.D. φ6/installed at the bottom right side of interior access port) | ||||||||||||

| ・Left side surface of the unit has a φ36 hole accessing to the interior. | ||||||||||||

| Internal dimensions | W505×H461×D386[mm] | |||||||||||

| Outer dimensions | W600×H643×D696 [mm] | |||||||||||

| Weight | approx. 90[kg] | |||||||||||

| Standard accessories | Power cable x 1 / fuse x 1 (in receptacle) / light plug x 1 | |||||||||||

|

*1: Must be no condensate in main unit. May not fulfill product specifications at temperatures other than the above environmental temperatures. *2: Voltage fluctuation tolerance ±10 [%] *3: At shipment, the internal setting temperature are adjusted so that the assumed temperature of the liquid in the flask is within +6.0±1.0 [°C] (@19.0 [°C]). *4: In environment temp. 19 [℃]. This does not include temperature changes due to the frost removal function. *5: The assumed temperature of the liquid in the flask is the temperature of the measuring rod located at the upper left rear inside the unit. *6: Activates when an irregular low temperature is detected. Forces the cooler to stop when it activates (with automatic reactivation) |

||||||||||||

| Item | Specifications | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Name | Low-temperature Incubator | |||||||||||

| Model | SLI-4090-B | |||||||||||

| Environmental conditions*1 | Environment temp. range | +18~22[℃] *2 | ||||||||||

| Power supply | AC100[V] 50/60[Hz] *3 | |||||||||||

| Rated current | 5[A] | |||||||||||

| Installation space | Ensure space of at least 10cm around the main unit | |||||||||||

| Temperature control | Internal temperature | Setting range | +3.0~10.0[℃] *4 | |||||||||

| Accuracy | ±2.5 [℃] (at center of inside) *5 | |||||||||||

| Temperature display | Digital display (1. internal temperature display, 2. flask interior fluid assumed temperature display) *4, 6 | |||||||||||

| Temperature correction | Single point correction | |||||||||||

| Cooling type | Refrigerator (freon gas R-134a filling volume 170 [g]) | |||||||||||

| Mixing type | Forced mixing by internal fan motor | |||||||||||

| Safety devices | Electrical leakage/overcurrent breaker, fuse (built in), sensor cut off, | |||||||||||

| sample protection high/low temperature alarm (factory settings *7), safety device for built-in HEPA filter | ||||||||||||

| (Circuit protector 1 [A], high temperature safety device 90 [℃]) | ||||||||||||

| Anti-icing thermostat *8 | ||||||||||||

| Output to external *9 | Temperature | Pt100 [Ω] sensor (-20 to +50 [℃]: 0 to 5[V]) | ||||||||||

| Alarm | High/low temp. alarm output (normal: open, error: close / AC250 [V] 1 [A] resistive load) | |||||||||||

| Other functions | ・Frost removal function (forced stop of refrigerator for approx. 15 mins once every 8 hours approx.) | |||||||||||

| ・Automatic condensate evaporator function | ||||||||||||

| ・Hose holder (for O.D. φ6/installed at the bottom right side of interior access port) | ||||||||||||

| ・Left side surface of the unit has a φ36 hole accessing to the interior. | ||||||||||||

| HEPA filter | ・Low pressure loss HEPA filter 400 × 400 × t50 [mm] | |||||||||||

| Air flow | approx. 3.0[㎥/min] | |||||||||||

| Manostar gauge | Pressure range 0 - 300 [Pa] | |||||||||||

| Internal dimensions | W505×H461×D386[mm] | |||||||||||

| Outer dimensions | W626×H830~900×D696 [mm] | |||||||||||

| Weight | approx. 110[kg] | |||||||||||

| Standard accessories | Power cable x 1 / fuse x 1 (in receptacle) / light plug x 1 / temperature sensor test report x1 | |||||||||||

|

*1: Cleanliness class of the installation environment is ISO class 7 or higher. *2: Must be no condensate in main unit. May not fulfill product specifications at temperatures other than the above environmental temperatures. *3: Voltage fluctuation tolerance up to ±10 [%] When decontaminating the room, turn off the breaker of the main unit and put the cover to the refrigerator air inlet. *4: At shipment, the internal setting temperature are adjusted so that the assumed temperature of the liquid in the flask is within +6.0±1.0 [°C] (@19.0 [°C]). *5: In environment temp. 19 [℃]. This does not include temperature changes due to the frost removal function. *6: The assumed temperature of the liquid in the flask is the temperature of the measuring rod located at the upper left rear inside the unit. *7: Sample material protect alarm setting: Low temperature -5 [℃]/high temperature 20 [℃] *8: Activates when an irregular low temperature is detected. Forces the cooler to stop when it activates (with automatic reactivation) *9: 2[m] cable from main unit, cable terminal: Y terminal ・High/low temperature alarm (normal: open, error: close (line color: black/green)) ・Temperature data (0 - 5 [V], line color: red/white) |

||||||||||||

Optional items that can be connected to Satake BioReactors

Development, Customization, and Single-use support of Exclusive Reactor in Accordance with Requirements Specifications

■Aeration unit

【Feature】

・Compact size for easy installation even in narrow spaces.

・Lightweight for air tank-style installations, eliminating the

need to find installation locations.

| Item | Specifications | |||||

|---|---|---|---|---|---|---|

| Name | Aeration Unit | |||||

| Model | SAU-3505 | SAU-3525 | SAU8050 | SAU80100 | ||

| Performance | Flow meter* | 50~500[NmL/min] | 0.2~2.5[NL/min] | 0.5~5[NL/min] | 1.0~10[NL/min] | |

| Compressor | Rated pressure | 6.86×104[Pa] (0.7[kgf・cm2]) | 9.81×104[Pa] (1.0[kgf・cm2]) | |||

| Rated flow rate | 3.5 [L/min] | 8 [L/min] | ||||

| Max. pressure | 9.81×104[Pa] (1.0[kgf・cm2]) | 1.47×105[Pa] (1.5[kgf・cm2]) | ||||

| Configuration | Flow rate adjustment | Constant flow valve for secondary pressure fluctuation | ||||

| Air outlet | O.D. φ8[mm] | |||||

| others | Outer dimensions | W136×H236×D306 [mm] | W136×H301×D306 [mm] | |||

| Power consumption | 0.25[A] 25[VA] | 0.6[A] 60[VA] | ||||

| Power supply | AC100[V] 50/60[Hz] | |||||

| Weight | approx. 6[kg] | approx. 8[kg] | ||||

| Remarks | Needle valve (air relief valve) built in | |||||

| *[NmL/min] or [NL/min] indicates the flow rate converted for 0 [℃] and 1 [atm] (101.3[kPa]) | ||||||

■Single-use pressure control system

【Feature】

・It can be connected to a glass culture tank or single-use

culture tank and the digital pressure switch regulates the

electromagnetic valve for maintaining the culture tank

pressure at a constant level.

・Fine tuning the opening of the manual bypass valve controls

hunting, enabling mild control.

| Item | Specifications | ||||

|---|---|---|---|---|---|

| Name | In-tank pressure controller | ||||

| Model | Si-P1 | ||||

| Display range | Pressure: -10.00 - 10.00 [kPa], Display accuracy: ± 2% (F.S. ± 1 digit) | ||||

| Setting range | Pressure: -10.50 - 10.50 [kPa] | ||||

| Control type | ON/OFF control | ||||

| Output | Analog signal: 1 - 5 [V] | ||||

| Casing | SUS304 (no paint), indoor type, non-drip proof, non-explosion proof specification | ||||

| Installation | Tabletop | ||||

| Outer dimensions | W125 × H100 × D225 [mm] | ||||

| Environment conditions | Pressure resist: 50 [kPa], temperature: 5 - 45 [℃], humidity: 20 - 85% RH (with no condensate) | ||||

| Utilities | AC100 - 240 [V] 50/60 [Hz] 0.5 [A] electrical outlet | ||||

■Cooling water circulator - Satake Cool Ace SCA-32

【Feature】

・It is a compact, tabletop type that can be installed even in

narrow spaces.

・In addition to cooling the heat producing components of the

BioReactor, it can be used for a variety of other purposes,

such as analytical equipment.

・Temperature control is achieved with a simple panel.

・Temperature settings range from -20 to 30 ℃ for versatile

applications.

・The circulation nozzle can be moved in 360°, reducing the

load on tubes.

【Use Case】

Culture tank, cooling tube attached to reactor tank, culture tank temperature controller, viscosity gauge, etc.

| Item | Specifications | ||

|---|---|---|---|

| Name | Coolant Circulator Cool Ace | ||

| Model | SCA-32 | ||

| Circulation type | Closed system directional circulation | ||

| Performance | Temperature control range | -20~30 [℃] | |

| Temperature accuracy | Setting -1 ~ -20 [℃]: ±2 [℃], setting 0 ~ 20 [℃]) ±1 [℃] | ||

| Cooling | -10[℃]:310 [W] 10[℃]:450 [W] 0[℃]:350 [W] | ||

| Circulation | Max. lifting height | 4.2 [m] ±0.5 / 5.6 [m] ±0.5 (50/60 [Hz]) | |

| Max. flow rate | 9 [L/min] / 10 [L/min] (50/60 [Hz]) | ||

| Function | Temperature control type | Refrigerator ON/OFF control | |

| Temperature setting/display | Sheet key digital setting configuration, switching digital display of measured temperature or set temperature (resolution: 1 [℃]) | ||

| Safety functions | Electrical leakage/overcurrent breaker, refrigerator overload relay, self-diagnostic functions (refrigerator error, sensor error, watchdog timer), refrigerator protection timer, circulation pump impedance protection |

||

| Optional functions | Flow control valve, metal nozzle, cool keeping hose set, trolley, product fixing parts, coolant communication cable, communication cable (for linking with NVC-3000) |

||

| Configuration | Temperature control | Electronic digital setting configuration and digital display | |

| Temperature sensor | Pt sensor | ||

| Refrigerator/refrigerant | Air-cooled, 450 [W], HFC, R-404A | ||

| Water tank | Total capacity 3.2 [L] approx. Actual capacity 2.7 [L] approx. Material SUS304 | ||

| Cooling coil | SUS316L | ||

| Circulation nozzle | O.D. 10 [mm] × I.D. 6.5 [mm] | ||

| Tank inner dimensions | W130×H115×D230 [mm] | ||

| Environment temp. range | 5~35 [℃] | ||

| Outer dimensions | W205×H545×D405 [mm] | ||

| Weight | approx. 28 [kg] | ||

| Power consumption | 8 [A]、 800 [VA] | ||

| Power supply | AC100 [V] 、50/60 [Hz] | ||

Cultivation, cleaning, and concentration in a single line!

Cell concentration cleaning system

As an improvement on the cell culture system, we sell a connected, completely closed system that consists of our reactor and attached Kaneka Corporation cell concentration cleaning system. This system can be customized upon request.

From culture to cell washing and concentration, this product enables consistent processing in a closed system, streamlining the work process. A pump is built into the cell wash concentrator body, making preparations unnecessary, enabling simple installation by following the pictures and colors on the accessories and body.

Disposable Kit for Cell Concentration Washer

●Sterilization method

Filter: γ sterilization

Circuit: EOG sterilization

●Safety

Passed the test specified by ISO10993(Cytotoxicity, sensitization, intradermal reaction, acute toxicity, hemolysis, pyrogenicity)

*Inquire to the contact details below if you wish to make a purchase.

Biomaster, Inc.

Cell strainer Circulation circuit Filtration circuit

| Item | Specifications | |||

|---|---|---|---|---|

| Name | [Cell Washing Concentration System] Tubing Pump System | |||

| Model | R-CS-S | |||

| Pump | Flow rate range | [Circulation pump] | 20 - 500 [mL/min] (depending on fluid temperature) | |

| [Feed pump / Drain pump] | 20 - 350 [mL/min] (depending on fluid temperature) | |||

| Accuracy | ±10 [%] | Pump diameter | φ80 | |

| No. of rollers | 2 | Clearance control | Automatic adjustment | |

| Applicable tube | [Circulation pump] | φ8.00 × φ12.00±0.15 [mm] (PVC based) | ||

| [Feed pump / Drain pump] | φ6.40 × φ 9.50±0.15 [mm] (PVC based) | |||

| No. of units | 2 | |||

| Valve | Type | Ultrasonic | Cutoff pressure | 750 [mmHg] and more |

| Applicable tube | φ3.50 × φ5.50 [mm] (PVC based) | |||

| No. of units | 4 | |||

| Pressure sensor | Type | Pressure transitor | ||

| Measuring range | -750 - 750 [mmHg] (pressure gauge) | |||

| Accuracy | ±5 [%] | |||

| Fitting | Luer lock | No. of units | 2 | |

| Display | Type | TFT color LCD | Effective display dimensions | 116×87 [mm] (5.7 inch) |

| Operational method | Touch panel (analog resistive film) | |||

| Outer dimensions | W450×H695×D400 [mm] | |||

| Weight | 43 [kg] | |||

| Power supply | AC100 [V], 50/60 [Hz], 360 [W] (cable length: 2 [m]) | |||

| Water proof protection class | IPX1 | |||

| Environment temperature | Operation: 15~35[℃]/Transportation: 0~50[℃] | |||

| Environment humidity | Operation: 35 - 85 [%] with no condensate / Transportation: 30 - 90 [%] with no condensate | |||

| Fluid temperature | 15~35[℃] | |||

| External color | SBY-S white (matte) / SBY blue (matte) | |||